Sunde Arctic EPS® and Sunde EPS®

Sunde Arctic EPS® and Sunde EPS®

Raw materials for producing insulating and shape molding products.

Go to products:

Sunde Arctic EPS® , Sunde Arctic 2nd Life 30 , Sunde EPS® , Sunde 2nd Life EPS®

Sunde Group laid the foundation for a whole industry when it developed EPS technology – the process by which styrene is converted into polystyrene.

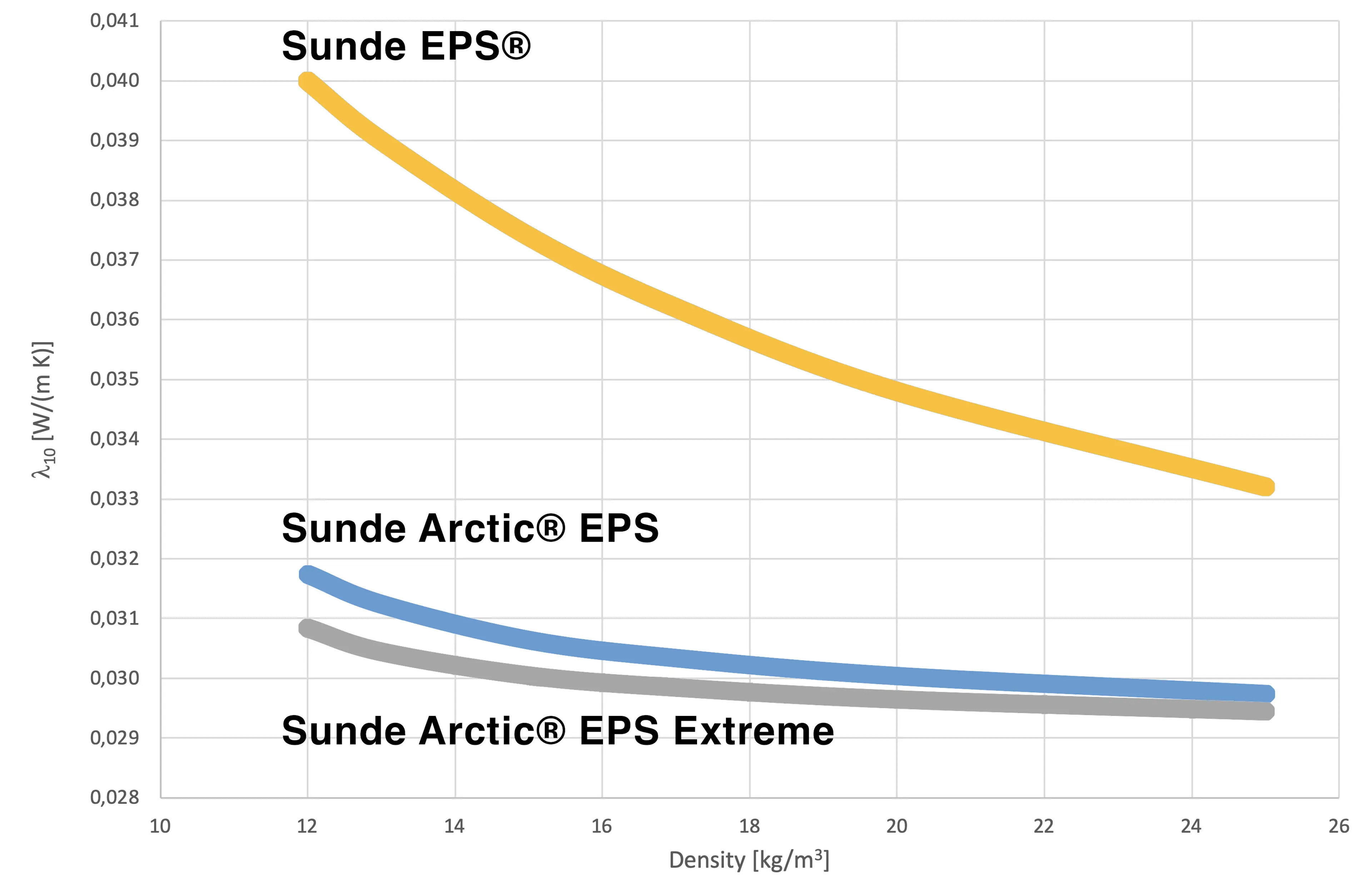

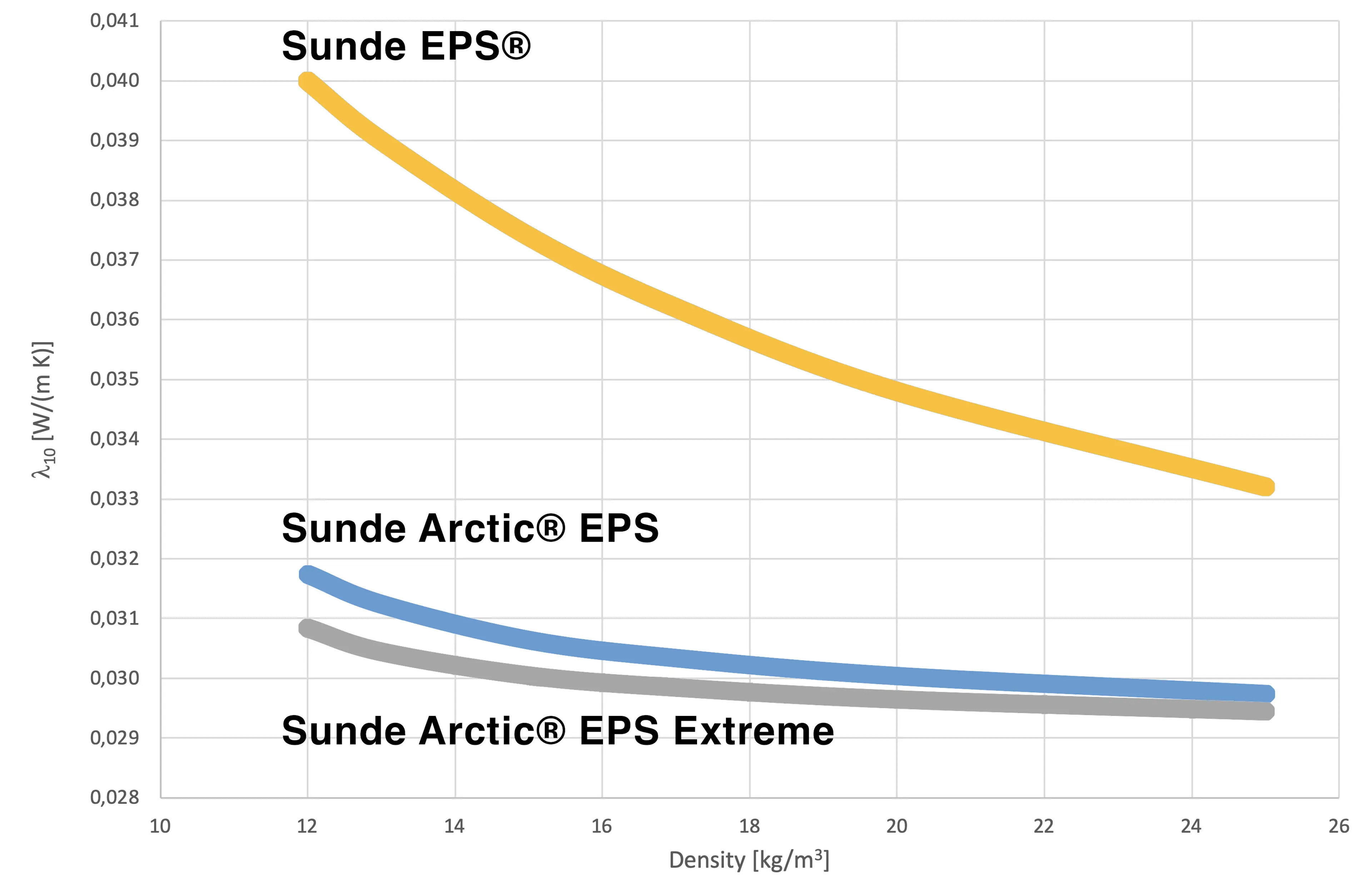

We currently offer two variants: Sunde Arctic EPS® and Sunde EPS®. The difference between the two is that Sunde Arctic EPS® has a 20% improved lambda value.

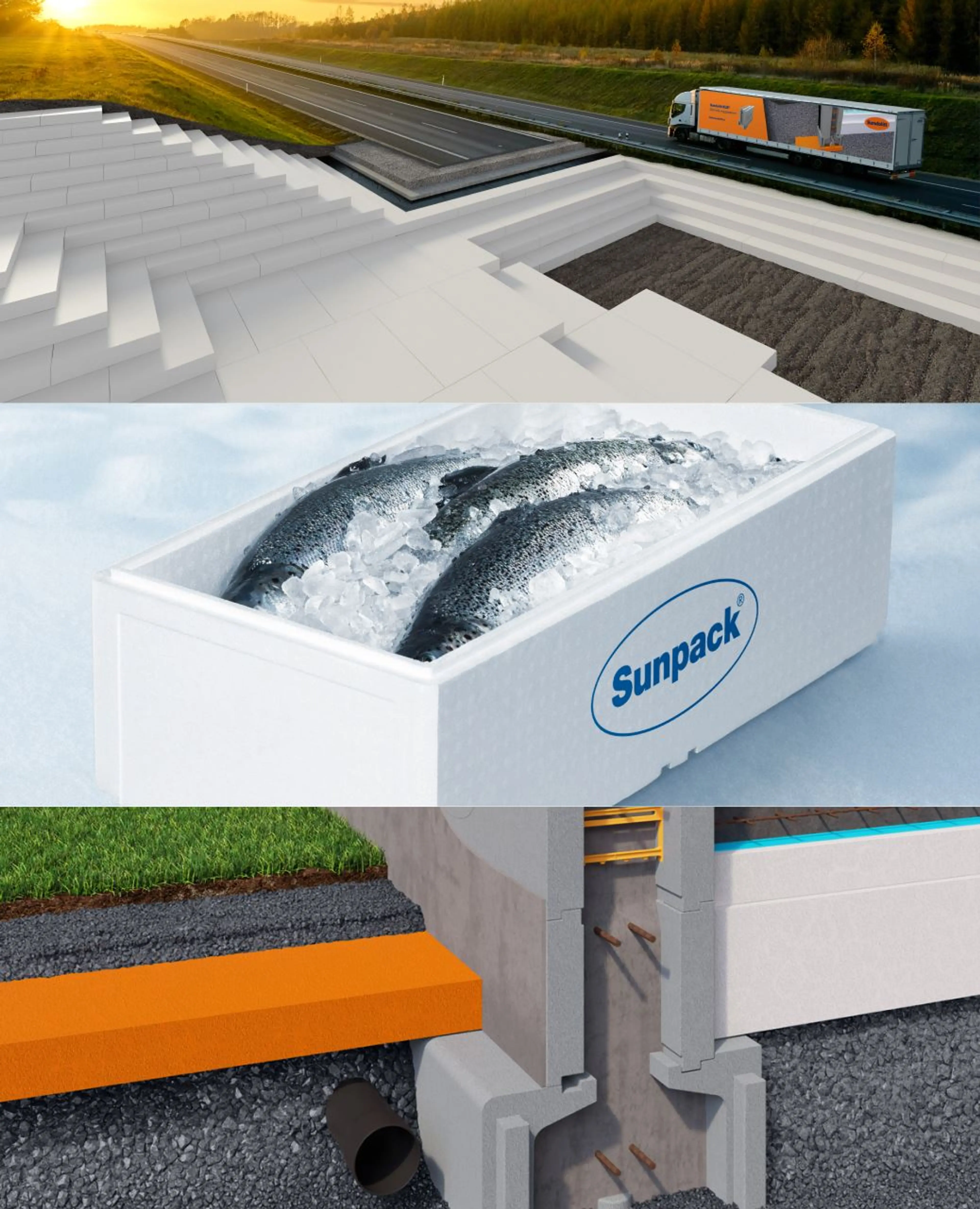

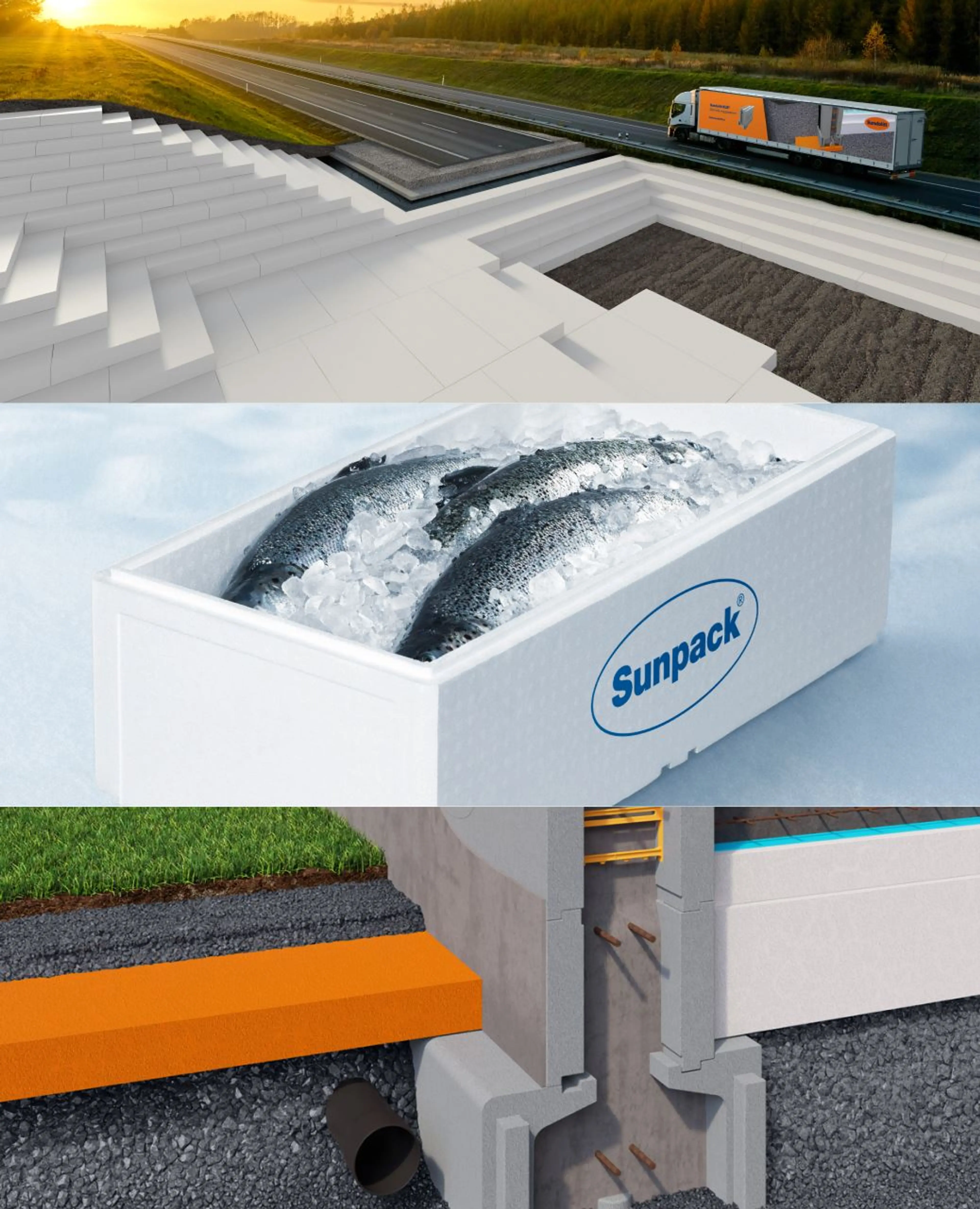

A wide range of applications

Sunde Arctic EPS® and Sunde EPS® are our raw materials used in the production of insulation products for building and construction, frost protection, road embankments, food packaging, technical packaging and other markets.

Short Cycle time

Good welding and high quality

Low energy consumption during process

Only 2% raw material

Sunde Arctic EPS® and Sunde EPS® form the basis for finished products that contain only 2% polystyrene substance. This ensures a high insulation value, which in turn enables low energy consumption.

100% recyclable

Sunde Arctic EPS® and Sunde EPS® are 100% recyclable, and can be recycled an infinite number of times.

Sunde Arctic EPS®

20% improved lambda value compared to standard EPS.

All Sunde Arctic EPS® products are also offered as Sundolitt 2nd Life™

A good product and environmental choice

Our raw materials have properties that contribute to less transport, less raw material consumption and a reduction in carbon emissions. In addition, the raw materials are 100% recyclable.

Sundolitt 2nd Life™

Our raw materials have properties that contribute to less transport, less raw material consumption and a reduction in carbon emissions. In addition, the raw materials are 100% recyclable.

Sundolitt White to Grey™

Our raw materials have properties that contribute to less transport, less raw material consumption and a reduction in carbon emissions. In addition, the raw materials are 100% recyclable.

We now offer products with a documented recycling rate of 30%

Our raw materials have properties that contribute to less transport, less raw material consumption and a reduction in carbon emissions. In addition, the raw materials are 100% recyclable.

*Mass balance is a set of rules for determining the use of recycled content in a final product when both recycled and new raw materials are used in the process. Example: Sunde Arctic 2nd Life 30-284 contains 30% recycled polystyrene.

Sunde Arctic EPS®

Sunde Arctic 283

Block moulding

- 1,1 - 1,5 mm bead size.

- 13 - 25 kg/m3 typical density finished product.

Sunde Arctic 284 Extreme

Block moulding

- 1,1 - 1,5 mm bead size.

- 13 - 25 kg/m3 typical density finished product.

- Lower lambda of finished product.

Sunde Arctic 283 SE

Block moulding

- 1,0 - 1,4 mm bead size.

- 13 - 25 kg/m3 typical density finished product.

Sunde Arctic 383

Shape/block moulding

- 0,7 - 1,1 mm bead size.

- 17 - 30 kg/m3 typical density finished product.

Sunde Arctic 2nd Life 30 EPS

Sunde Arctic 2nd Life 30-283

Block moulding

- 1,1 - 1,5 mm bead size.

- 13 - 25 kg/m3 typical density finished product.

Sunde Arctic 2nd Life 30-283 SE

Block moulding

- 1,0 - 1,4 mm bead size.

- 13 - 25 kg/m3 typical density finished product.

Sunde EPS®

Sunde 121 Standard

Standard block moulding, low density.

- 1,6 - 3,0 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 123 Standard

Standard block moulding, low density.

- 1,6 - 3,0 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-20 kg/m3 typical density finished product.

Sunde 223 standard

Block moulding, low density. Civil engineering application.

- 1,0 - 1,6 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 224 standard

Block moulding, high density.

- 1,0 - 1,6 mm bead size.

- 13 kg/m3 recommended min. foaming density.

- 15-30 kg/m3 typical density finished product.

Sunde 322 standard

Shape moulding, fish-boxes, standard block moulding.

- 0,6 - 1,0 mm bead size.

- 15 kg/m3 recommended min. foaming density.

- 18-40 kg/m3 typical density finished product.

Sunde 151 SE

SE block moulding, low density.

- 1,6 - 3,0 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 253 SE

SE block moulding, medium density.

- 1,0 - 1,6 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 352 SE

SE shape-/block moulding. Wall thickness >10 mm. High density.

- 0,6 - 1,0 mm bead size.

- 14 kg/m3 recommended min. foaming density.

- 18-40 kg/m3 typical density finished product.

Sunde 2nd Life 30 EPS®

Sunde 2nd Life 30-223 standard

Block moulding, low density. Civil engineering application.

- 1,0 - 1,6 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 2nd Life 30-224 standard

Block moulding, high density.

- 1,0 - 1,6 mm bead size.

- 13 kg/m3 recommended min. foaming density.

- 15-30 kg/m3 typical density finished product.

Sunde 2nd Life 30-322 standard

Shape moulding, fish-boxes, standard block moulding.

- 0,6 - 1,0 mm bead size.

- 15 kg/m3 recommended min. foaming density.

- 18-40 kg/m3 typical density finished product.

Sunde 2nd Life 30-151 SE

SE block moulding, low density.

- 1,6 - 3,0 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 2nd Life 30-253 SE

SE block moulding, medium density.

- 1,0 - 1,6 mm bead size.

- 12 kg/m3 recommended min. foaming density.

- 12-25 kg/m3 typical density finished product.

Sunde 2nd Life 30-352 SE

SE shape-/block moulding. Wall thickness >10 mm. High density.

- 0,6 - 1,0 mm bead size.

- 14 kg/m3 recommended min. foaming density.

- 18-40 kg/m3 typical density finished product.

Do you want to know more about Sunde Arctic EPS® and Sunde EPS®?